The Technology

Sushi Rice Smoothing and Controlling System

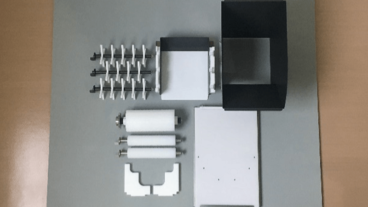

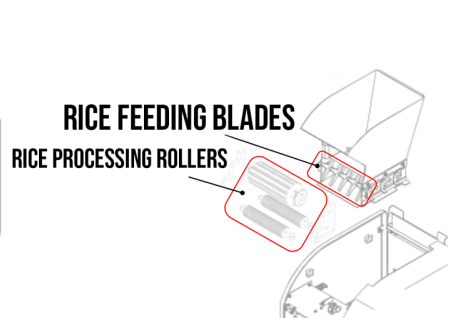

There are 3 sets of rice feeding roller system with 14 blades that can unravel the sushi rice evenly and make the rice sheet smooth and even.

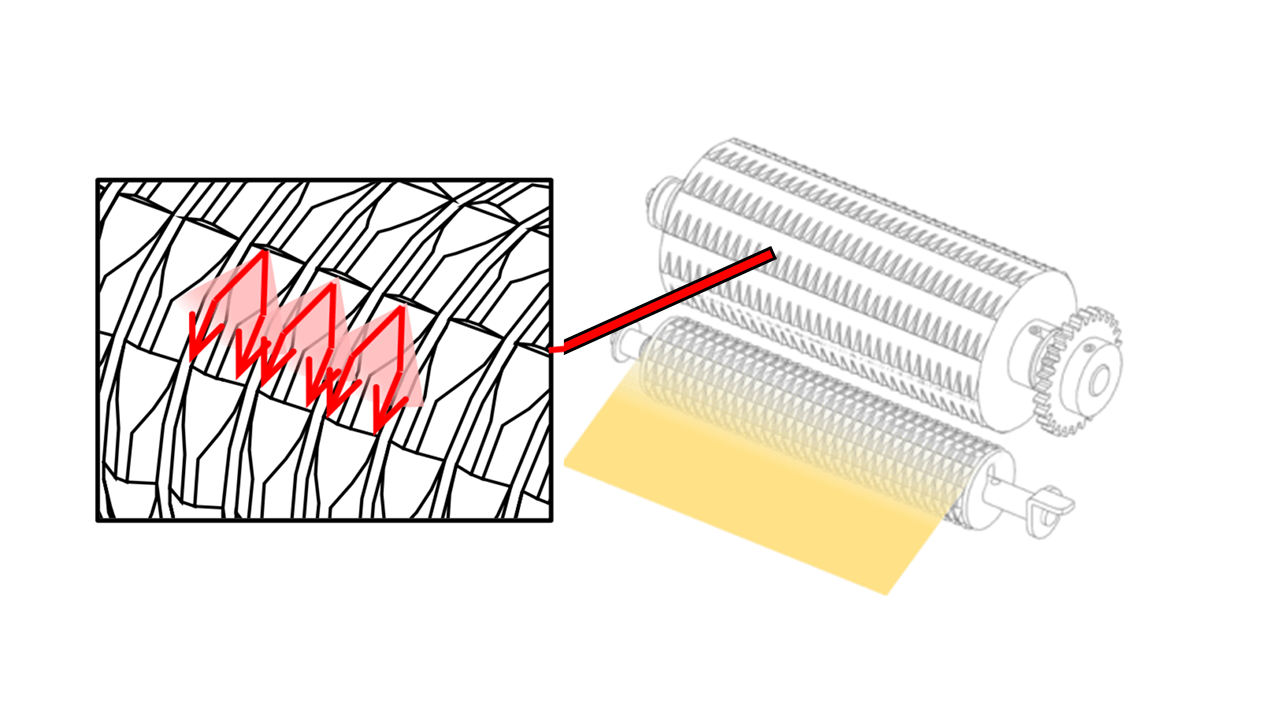

Patented Utility Rollers

- The surface of the rice feeding utility rollers was specially designed and developed for rice pressing and spreading.

- The individual fan-shaped texture can help create rice sheets uniformly with the perfect amount of pressure.

- The combination of one larger and one small roller on top of each other mimics the pressure and special techniques used by Japanese sushi chefs.

- The rollers are made with Ultra High Molecular Polyethylene/ It is non-stick, heat resistance, chemical resistance, and water absorption resistance. Very durable.

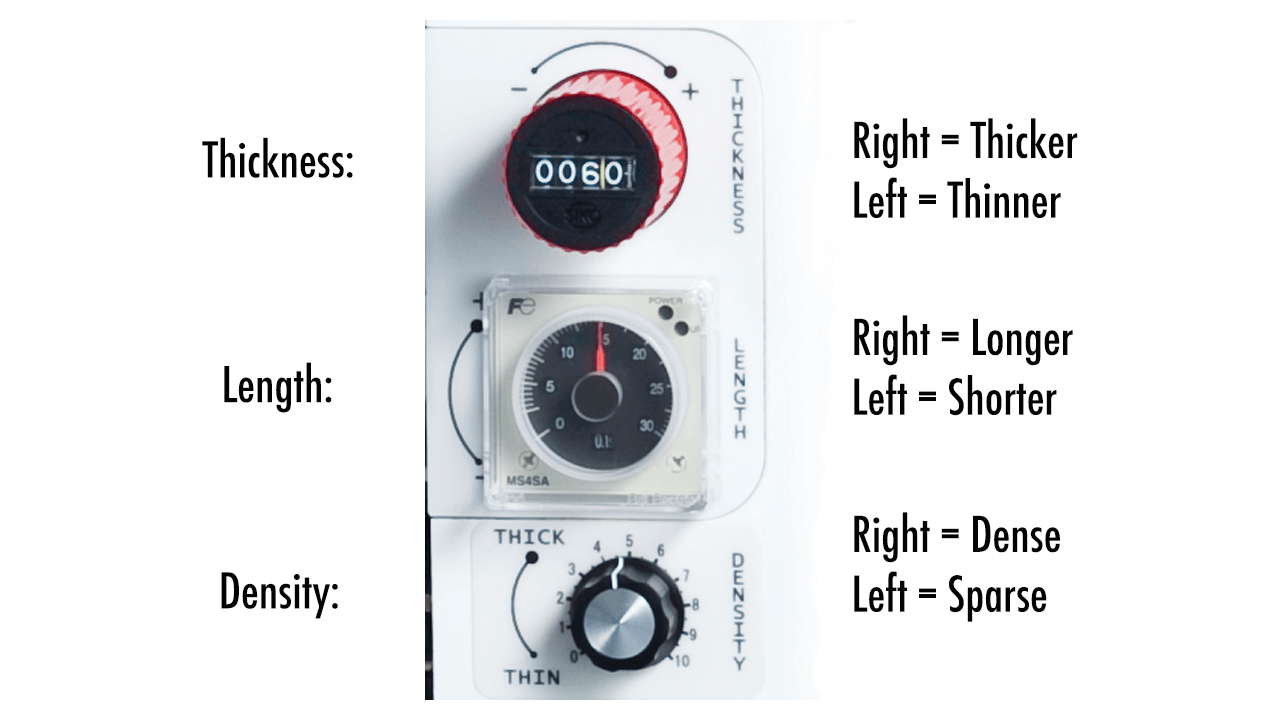

Rice Sheet Adjustment Controls

The sushi roll machine comes with an easy to use rice sheet adjustment control panel. You can easily adjust the density, thickness and the size of the rice sheet.

- The density of the rice sheet can be easily controlled through a volume dial. If the rice sheet is too sparse, it is recommended to set the dial higher, and if rice sheet too dense, dial the density down a bit.

- The thickness of the rice sheet is also a volume dial. Turn to the right and the rice sheet is thicker and left is thinner.

- The length of the rice is another volume dial. The right is longer and left is shorter.

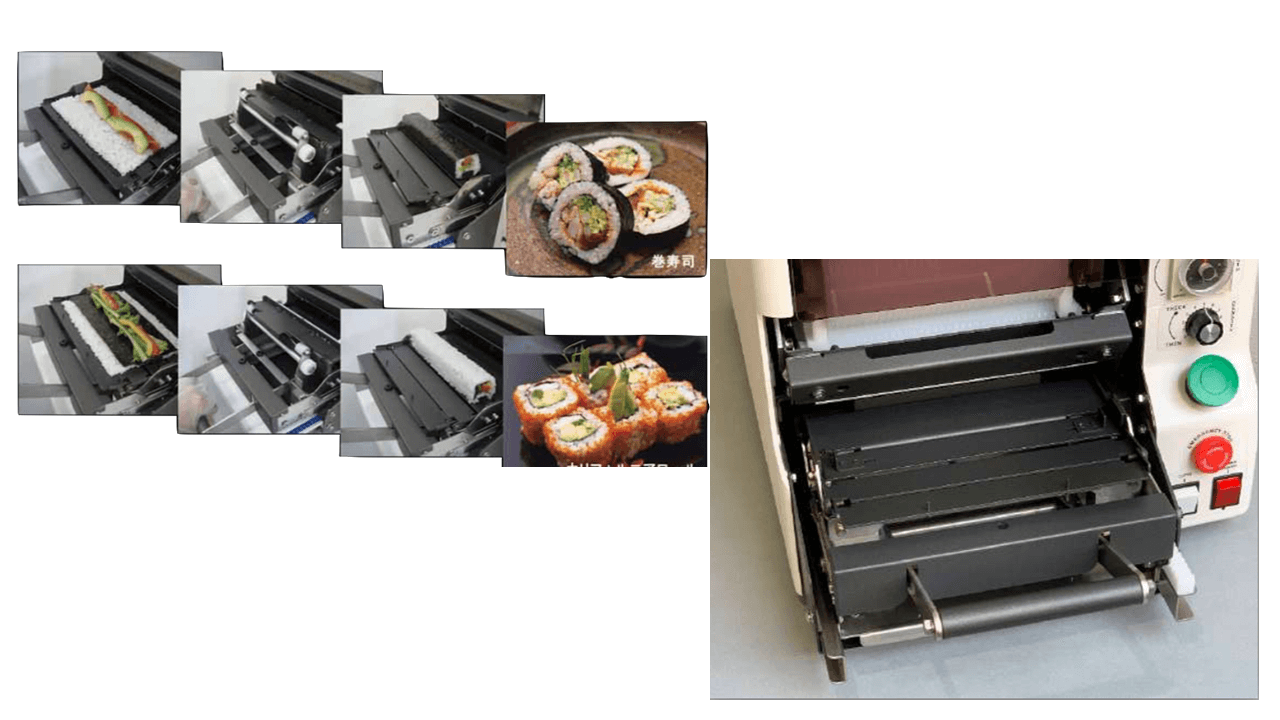

Rolling System

With this rolling system, anyone can become a sushi chef. It has been perfected for over 25 years.

- Tough and durable, made of stainless steel 304. Can withstand more than 500,000 times of continous open-close action. Coated wit Dupont teflon for anti-stick properties.

- Capable of making different kinds of sushi rolls, such as norimaki, uramaki, and spiral uramaki.

- Can easily adjust the tightness of the rolls

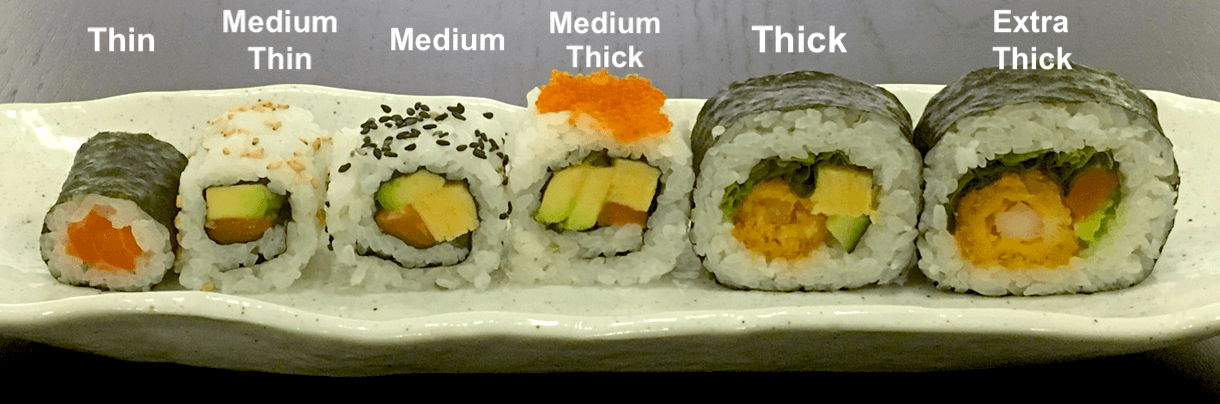

- Capable of rolling 6 different size of sushi rolls

| Size | Roll Unit Size | Weight per Roll *approx. |

|---|---|---|

| Thin | 25 x 25 mm | 80-100g |

| Medium Thin | 30 x 30 mm | 100-130g |

| Medium | 35 x 35 mm | 130-150g |

| Medium Thick | 40 x 40 mm | 150-200g |

| Thick | 45 x 45 mm | 200-250g |

| Extra Thick | 50 x 50 mm | 250-300g |

Maintenance and Cleaning

Durability

Videos

Sushi Roll Thickness

| Size | Dimensions(mm) | Grams(g) *approximately |

|---|---|---|

| Thin | 25 x 25 | 80~100 |

| Medium Thin | 30 x 30 | 100~130 |

| Medium | 35 x 35 | 130~150 |

| Medium Thick | 40 x 40 | 150~200 |

| Thick | 45 x 45 | 200~250 |

| Extra Thick | 50 x 50 | 250~300 |

* The rice sheets produced can be from 80~300g depending the desired sushi thickness/size.

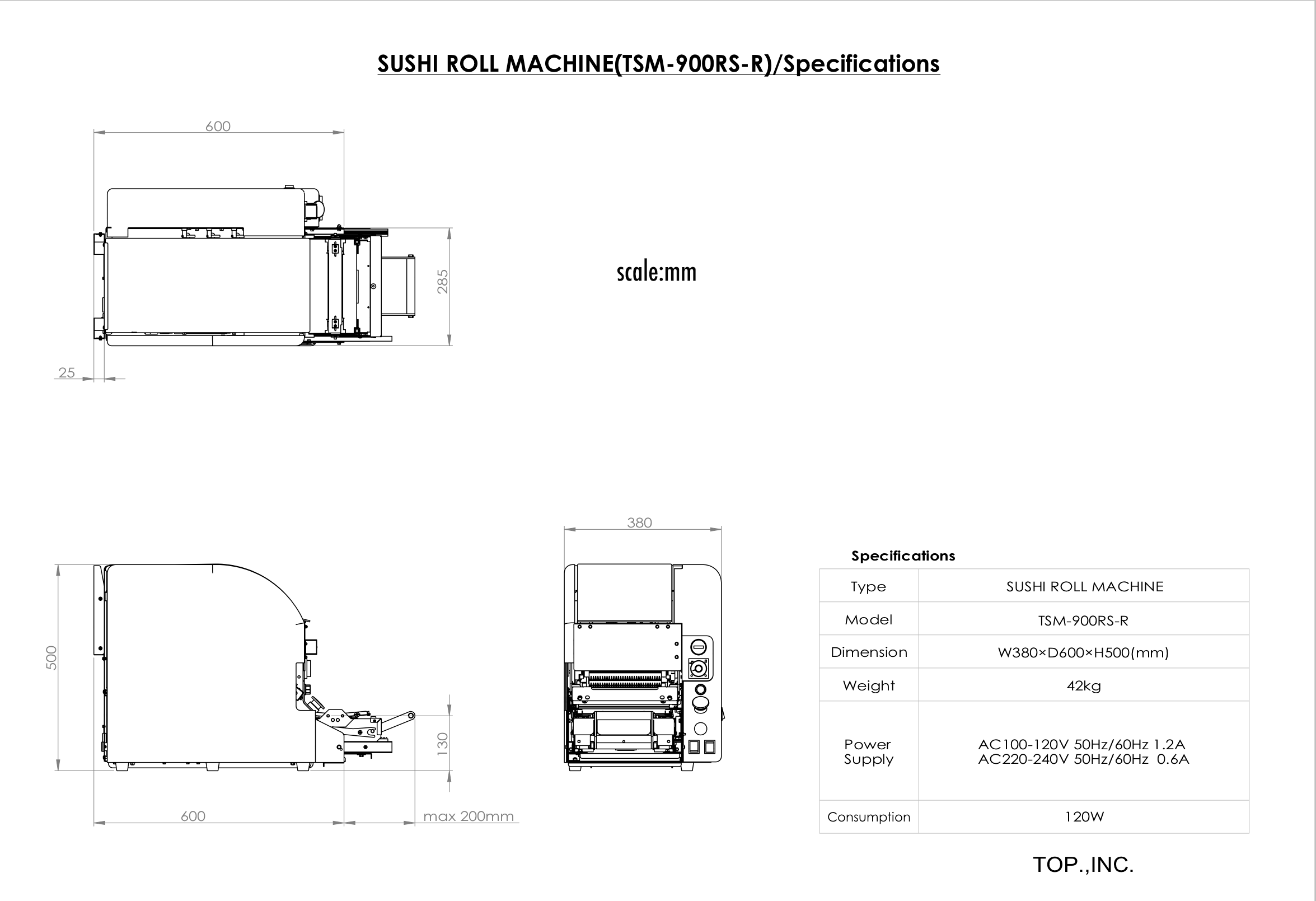

Specification

| Product: | Sushi Roll Machine For Rice Sheet | ||

|---|---|---|---|

| Standard: | UL/NSF, CSA, CE | ||

| Production Capacity: | 600 sheets per hour, 1 every 6 sec, 2~4 rolls per min | ||

| Type A | |||

| Country of Use | USA, CANADA | Voltage | 100-120V |

| Type B | |||

| Country of Use | EUROPE, OCEANIA, ASIA, SOUTH AMERICA | Voltage | 220-240V |

| Dimension: | W380 x D570 x H500mm | ||

|---|---|---|---|

| Body Weight: | 42kg | ||

| Power Consumption: | 120W | ||

| Sushi Rice Capacity: | 9kg | ||

| Option: | |||

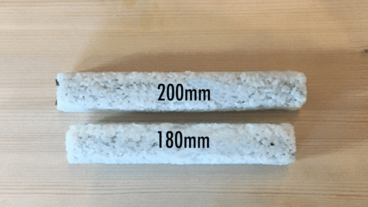

| Roller Unit (rice sheet width) | Normal: 180mm | Wide: 200mm | Multi: both 180 and 200mm |