The Maki Sushi Machine: Sushi Production Simplified

Starting a sushi business can be a daunting task. While it is full of the delicious prospects of profits and happy customers, large scale sushi production has always been a choking point when it comes to sales.

As many of you will know, the process of making sushi is a complex one, requiring years of training, hard work, subtlety and deliberation in order to master. This is the biggest obstacle to overcome to make it viable for large scale production to be possible.

So how do we achieve this?

Let us take a look to find out!

Quick Navigation

Working With the Best Chefs in The Sushi Industry :

In order to make a sushi machine that is capable of creating sushi in large amounts without compromising on quality, we worked alongside the best sushi chefs in Japan to create the TSM 900 RSR.

This maki sushi machine is designed specifically to be able to produce very large quantities of maki sushi [600 sheets per hour 1 every 6 sec, 2~4 rolls per min] to simplify the production process and enable large scale distribution without compromising on quality. We have worked tirelessly with our chefs in order to fine tune the details that help our maki sushi stand out as a truly fine dining experience.

In this article, we will take a look at our maki sushi machine and see how you can maximize your production capacity while still delivering a Truly Authentic Japanese Dining Experience – A Top Sushi Guarantee!

A Revolutionary Sushi Making Control System :

Our Maki Sushi Machine comes with an advanced Sushi Control System comes with three sets of rice feeding rollers, each with 14 blades, that can uniformly unravel sushi rice and produce a smooth and even rice sheet.

Air-in-Forming Rollers :

Newly developed rollers imitate the quality of a sushi chef crafted maki rice sheet with perfect air to rice ratio.

The Maki Sushi Machine also comes with a set of utility rollers specially designed through research and development alongside the best sushi chefs in Japan to bring you the most delicious maki sushi. These Maki Sushi Machine Rollers boast a range of exciting features including :

- The rice feeding utility rollers’ surface was created and developed specifically for rice pressing and spreading.

- Distinctive fan-shaped texture can aid in the uniform creation of rice sheets with just the right amount of pressure.

- Pressure and specific procedures employed by Japanese maki sushi chefs are simulated by stacking one larger and one smaller roller on top of each other.

- Rollers are manufactured using Ultra High Quality Materials, leading to a device that is non-stick, heat resistant, chemically resistant, and resistant to water absorption. Very long-lasting.

Customize the thickness of your Uramaki and Maki Rice Sheets :

The rice sheet adjustment control panel on the maki sushi machine is simple to use. The rice sheet’s density, thickness, and size are all simply adjustable. The dials and controls on the maki sushi machine are very easy to use and maintain.

- A volume dial allows you to quickly alter the density of the rice sheet.

- Set the density up a notch if the rice sheet is too sparse, and down a notch if the rice sheet is too solid.

- The rice sheet thickness can also be used as a volume control.

- The rice sheet on the right is thicker if you adjust the right dial, while the one on the left is thinner and vice versa.

- Another volume dial is the length of the rice. The right side is longer, while the left side is shorter.

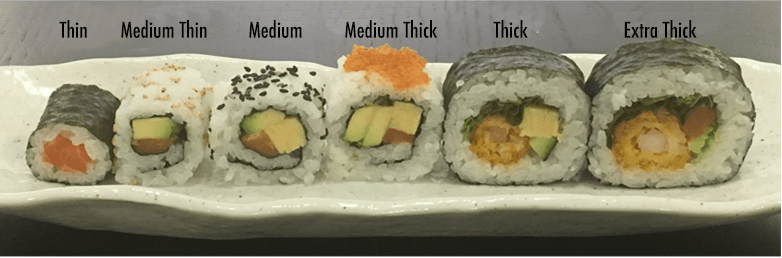

Varying Degrees of Thickness :

Using the customizable dials on the maki sushi machine, it is possible to adjust the thickness and density of your sushi at the touch of a button.

Keep in mind that the thickness of your maki sushi should be set to an amount that is capable of carrying the additional ingredients you place within it.

Extremely Durable Machinery :

The maki sushi machine boasts a high quality motor that is capable of extended use without overheating issues. It comes with the durability and resistance of stainless steel as well as a sensor to protect the machine against water and oil damage.

Our maki sushi machines are built to last decades but even in the case of minor breakage, most of the parts are quite easy to replace and fix at a moment’s notice. If you have a question or require assistance related to one of our maki sushi machines, please do not hesitate to contact us.

If you would like to look more into the specifications of this maki sushi machine or other sushi machines, please feel free to peruse our product pages.

In Conclusion :

We hope this article has been useful in helping you understand the process by which maki sushi making can be elevated to large scale production.

At Top Sushi, we make a promise to quality and authenticity and this is something that will be evident when you choose to use our sushi machines for your business.

Join the Top Sushi Family and add your marker to the map to claim exclusive benefits, consultation, seasonal discounts and more!

If you would like to know more about our sushi machines, would like to purchase our maki sushi machine or would like to schedule a one on one consultation with one of our sushi specialists, please do not hesitate to reach out to us on our contact page!

If you want to find out more about future proofing your sushi business have a look at the following articles:

Business Optimization for Sushi Professionals

Sushi Equipment that Changes Modern Sushi Production

Nigiri Sushi Maker: The Change for Affordable Sushi