The Technology

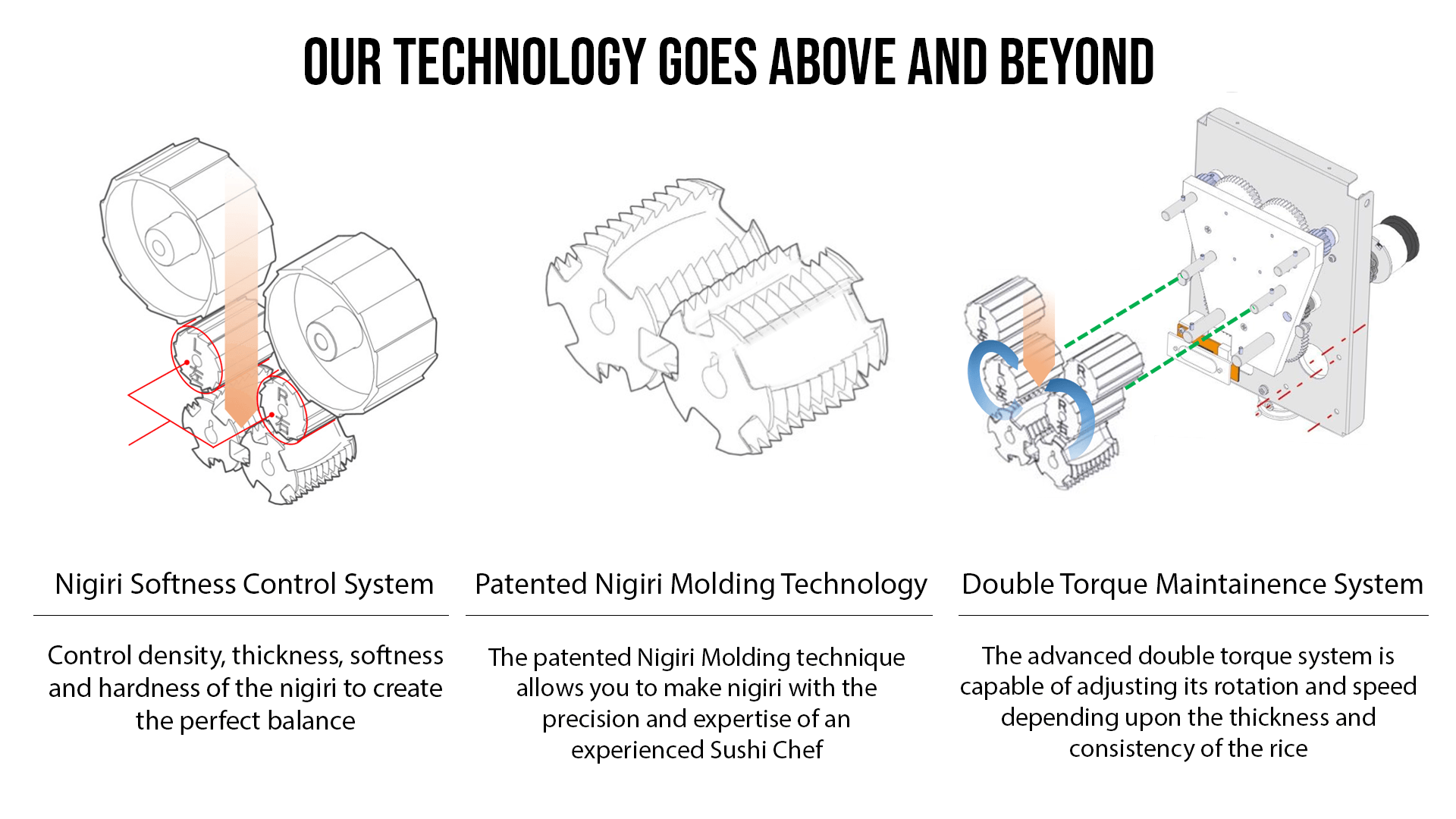

Patented Nigiri Molding Technology

- The specially designed molders allow for exceptional fluidity and control over the texture and mold ability of the Nigiri Balls just like an experienced Sushi Chef

- The highly advanced resin cutting technology is used for mold cutting and shaping in order to create well-formed Nigiri balls

- The combination of one larger and one small roller on top of each other mimics the pressure and special techniques used by Japanese sushi chefs.

- The rollers are made with Ultra High Molecular Polyethylene/ It is non-stick, heat resistance, chemical resistance, and water absorption resistance. Very durable.

Sushi Rice Smoothing and Controlling System

The Nigiri Ball “Softness – Hardness” adjustment system allows for a deicious and uniformed sushi ball making system. This system ensures that the Nigiri is produced evenly with uniform texture and softness so as to allow for maximum reliability and control.

Rice Ball Adjustment

The TSM – 07 Sushi machine comes with an easy to swap thickness adjustment roller. You can easily adjust the density, thickness and the size of the rice balls.

- The weight and density of the rice rice ball depends upon the roller that is being used. Various rollers can be used to product Nigiri Sushi of various volumes from 16g to 30g

- The thickness of the rice sheet is also a volume dial. Turn to the right and the rice sheet is thicker and left is thinner.

- Depending upon the volume of the sushi, they may be used for various purposes in different establishments from restaurants to super markets and take away

Maintenance and Cleaning

Durability

Nigiri Rice Ball Sizing

| Gram (g) | Dimensions (mm) |

|---|---|

| 16 | W24xD53xH20 |

| 18 | W25xD53xH21 |

| 20 | W26xD53xH22 |

| 22 | W27xD53xH23 |

| 24 | W29xD53xH23 |

| 26 | W30xD53xH25 |

| 30 | W33xD53xH28 |

Video

Specification

| Product Name: | Sushi Nigiri Machine | ||

|---|---|---|---|

| Standard: | UL/NSF, CSA, CE, IAPMO(UL/NSF, CSA) | ||

| Production Capacity: | 2,800 sushi balls per hour with 16, 18, 20, 22 or 24g rollers | ||

| Type A | |||

| Country of Use | USA, CANADA | Voltage | 100-120V |

| Type B | |||

| Country of Use | EUROPE, OCEANIA, ASIA, SOUTH AMERICA | Voltage | 220-240V |

| Dimension: | W300 x D480 x H590mm | ||

|---|---|---|---|

| Body Weight: (Machine Only) | 23kg | ||

| Power Consumption: | 80W | ||

| Sushi Rice Capacity: | 4.5kg | ||

| Option: | |||

| Roller Unit (Nigiri size) | Normal: 16/18/20/22/24/26/30g | Towara: 25/30g | |